Machining

Specialised Automotive Machining

Jack Brothers is the one-stop-shop for all your Automotive Machining requirements. With over 45 years experience and the latest technology, our ongoing commitment to the HIGHEST QUALITY for your engine application.

With our in-house Super Flow ENGINE DYNO, AIR-FLOW benches and Cam Analysis system we can help you maximize the horsepower potential of your combination. We also continue to invest in the latest technology so you get unsurpassed quality and peace of mind that your job will be done right the first time. We regularly do machining for One to Twelve Cylinder Engines

- CUSTOM CNC programs for your SPECIAL needs

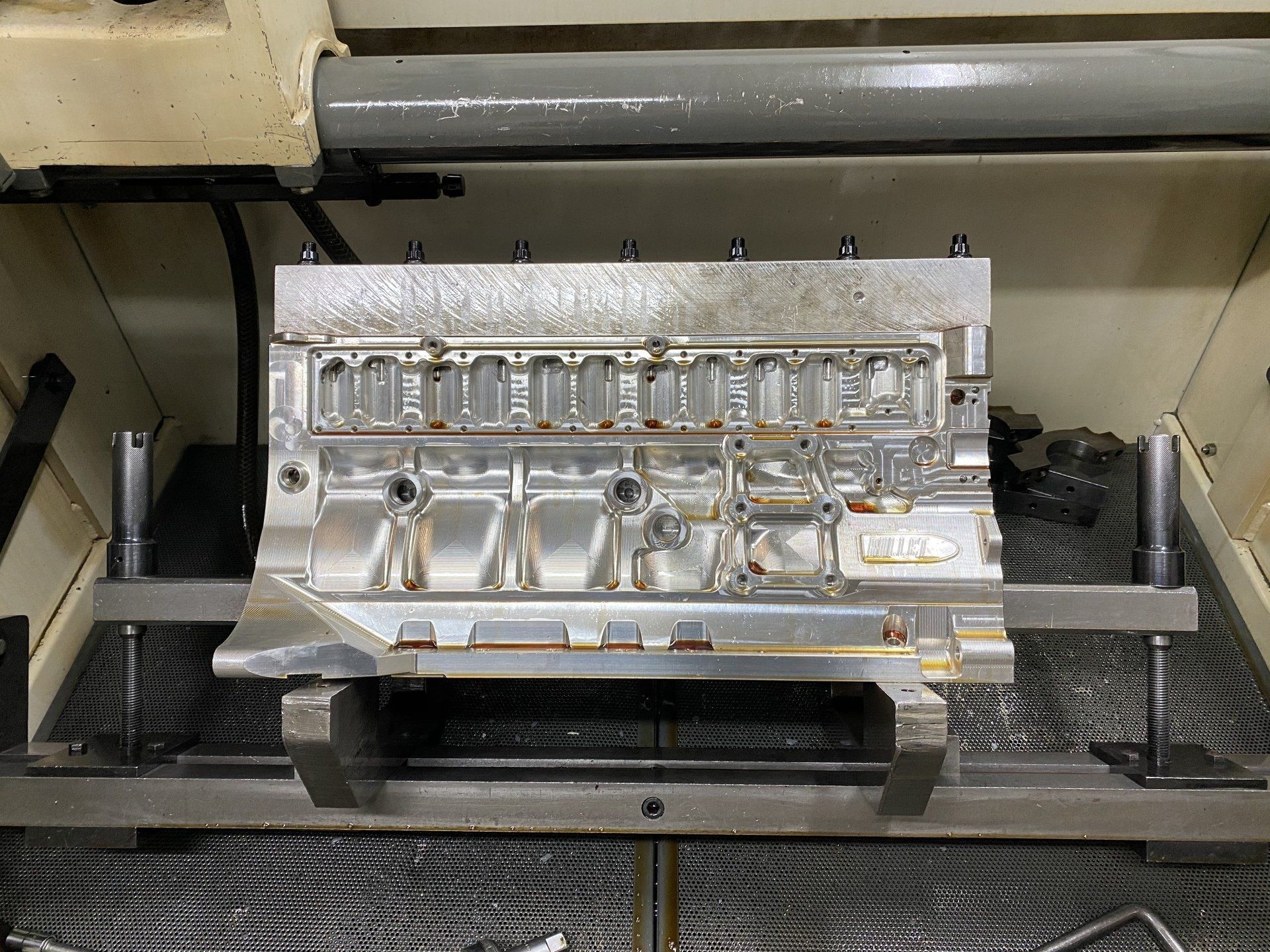

- ROTTLER F65 AND F67A/69 MACHINING CENTRES Update with Renishaw Digitizer.

- TOOLING for HARLEY [INC. NITRO]and SUBARU and ALL other COMMON RACE ENGINES

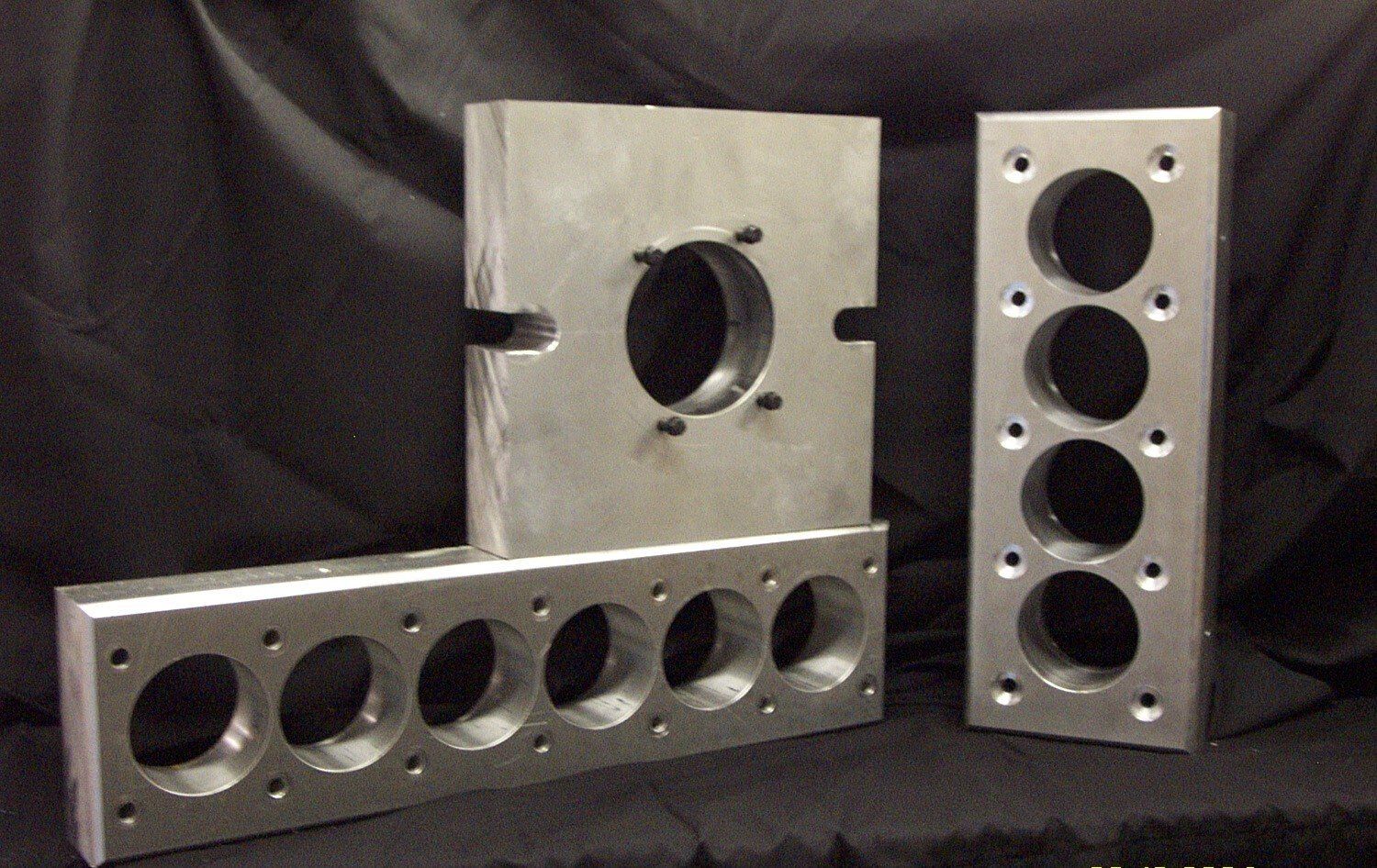

- Block and cylinder head Machining for O' rings, Receiver Grooves and FIRE RINGS

- CNC Port & Manifold O"RINGING

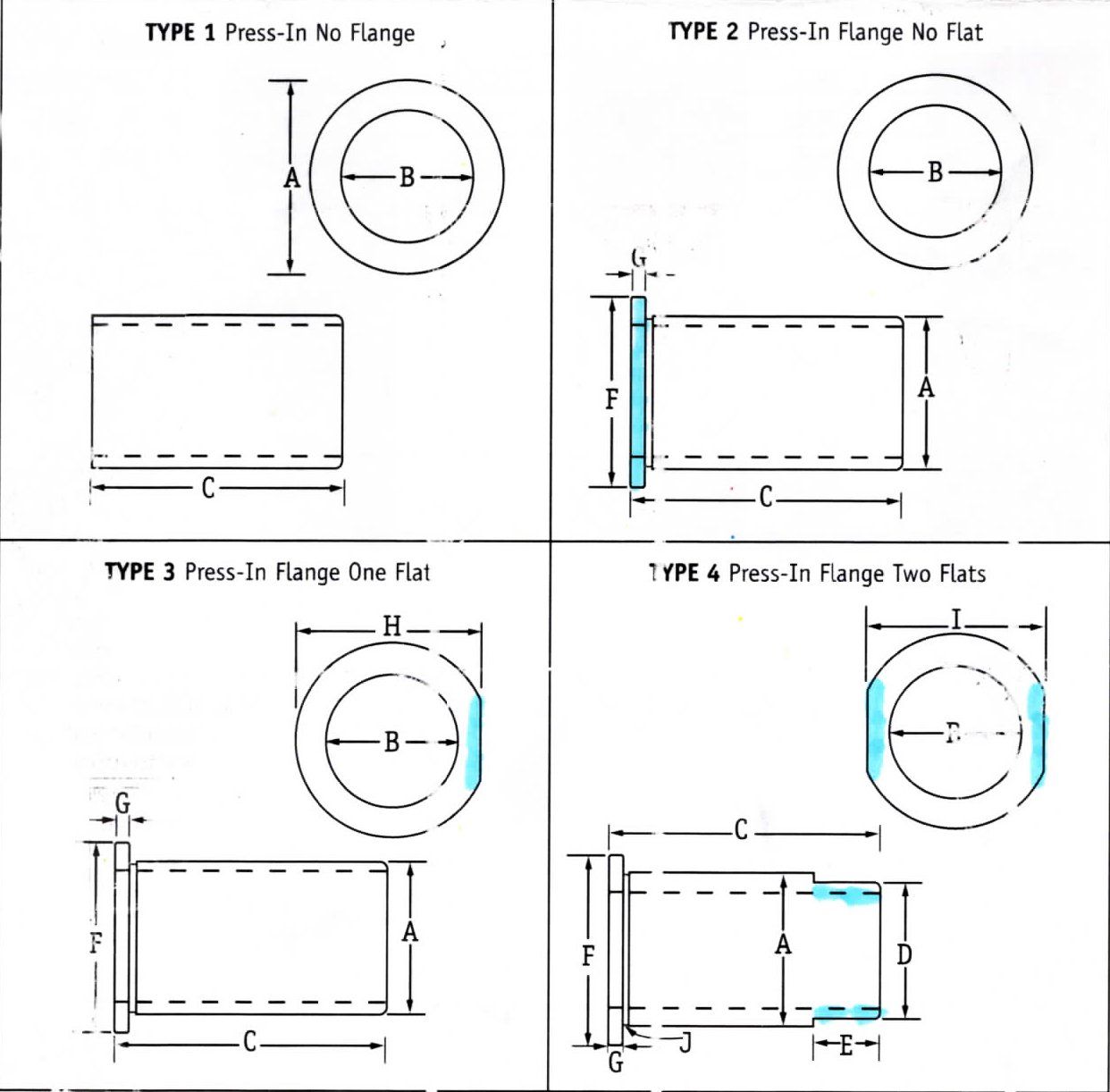

- Machining engine blocks for all types of Cylinder SLEEVES, Flange type n mid sleeves etc.

- Machine Cam tunnel for ROLLER cam bearings and larger 50-55-60mm etc.

- CNC MACHINING the decks of cylinder heads and engine blocks.

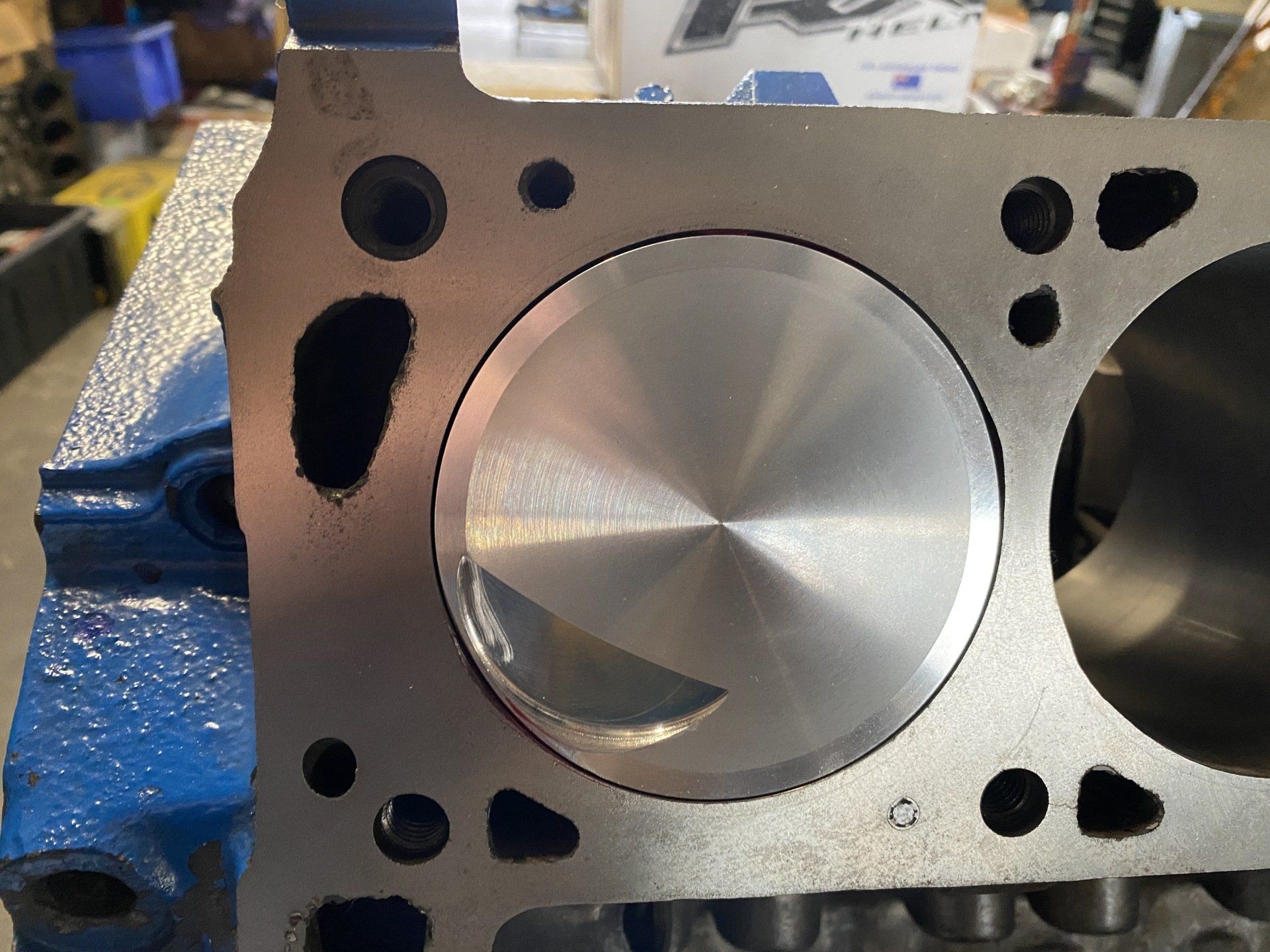

- CNC CYLINDER BORING and DECKING to Blueprints

- LIFTER bores Machined for Sleeves and Oversize lifters JESEL Keyway etc.

- CWT Balancing ENGINE COMPONENTS, INC. CAMSHAFTS

- BERCO 225 Crank grinding AND POLISHING @ CYLINDRICAL GRINDING

- above to mounted bearings

- BERCO CYLINDER BORING: CENTERS ON ORIGINAL BORES

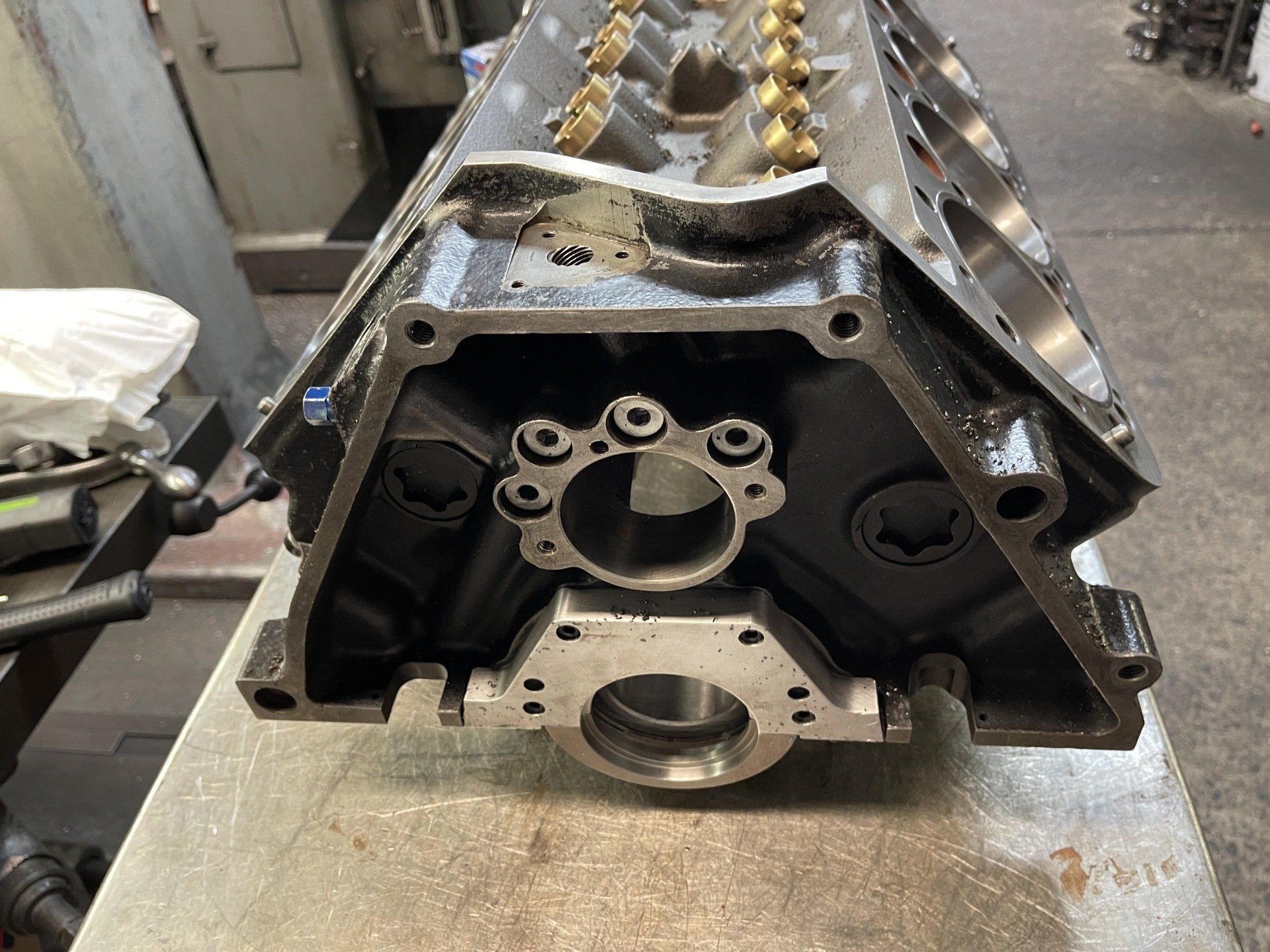

- MAIN Tunnel LINE Boring and SUNNEN Honing

- FITTING STEEL CAPS AND GIRDLES

- MACHINING FOR LARGER MAIN AND HEAD STUDS ETC.

- MACHINING Piston VALVE RELIEFS @ DECKS ETC.

- DAMAGED Blocks & Cylinder Heads

REPAIRED Aluminum. CNC AFTER

- Cylinder HEAD

PORT

Development

- SERDI SEAT AND GUIDE & Insert MACHINING ETC

- COMBUSTION Chamber VOLUMES MEASURED

- MANIFOLD

MATCHING

TO HEAD PORTS

- MEGA FLOW 1200cfm & SUPER FLOW 110 cylinder head Flow Benches

- Super flow Engine Dyno

- Cam Pro Plus analysis of camshafts.

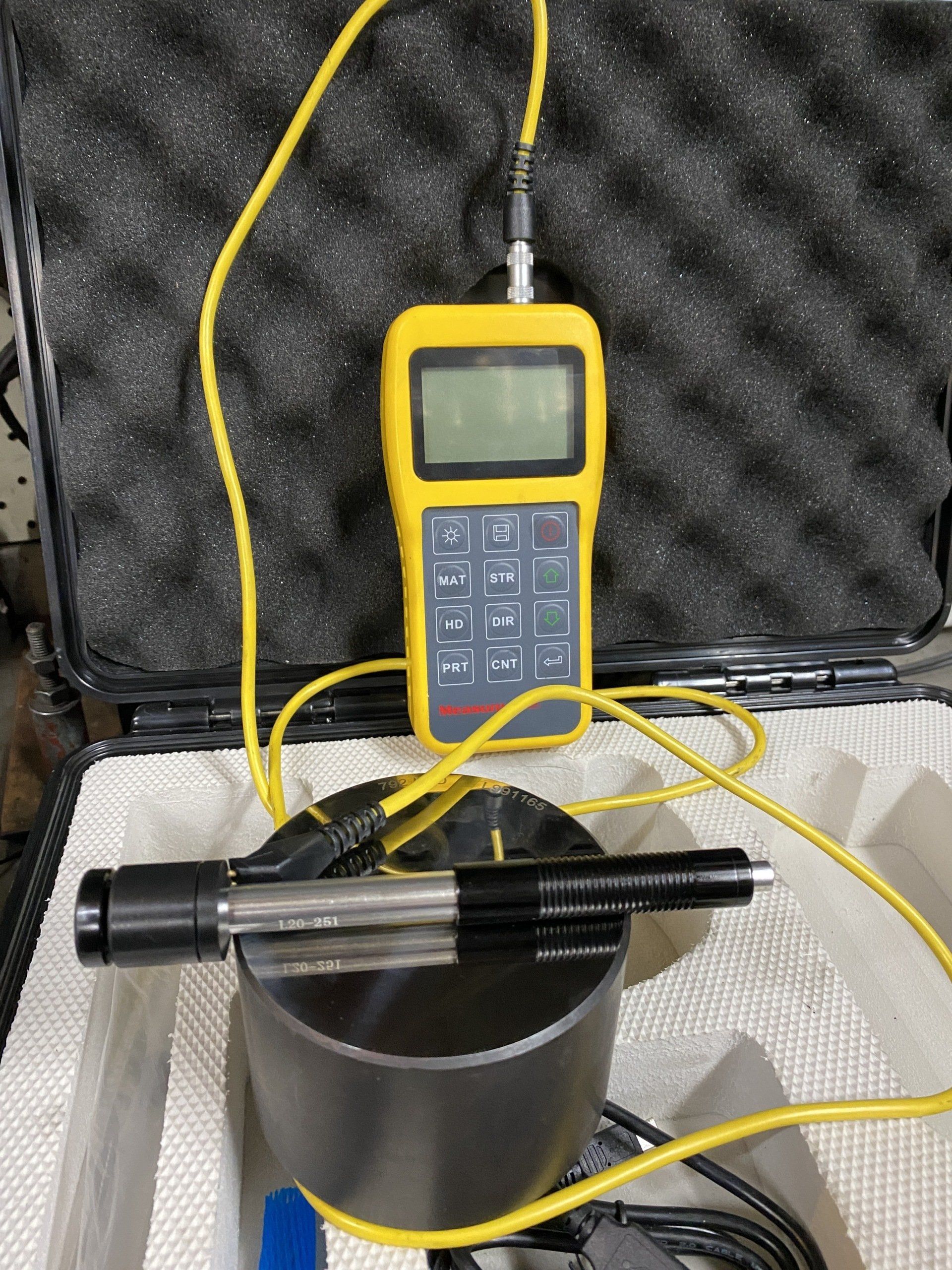

- ULTRA Sonic

testing of cylinder wall thickness etc.

- SURFACE FINISH TESTING RA CYLINDER BORES AND DECKS ETC ,

- HARDNESS TESTING OF METALS: BRINNEL

- TIG welding Ali and steel, MIG & PLASMA

- SUNNEN Torque plate Honing cylinder walls

- SUNNEN honing lifter bores

- SUNNEN Rod resizing, AND ALIGNMENT

- SUNNEN pin bush and piston pin honing up vary large sizes

- SUNNEN HONING HARD MATERIALS

- HOT TANK 90C cleaning of cast iron and steel engine components

- Tumbler cleaning of components

- Media

blasting

of components

- CRACK TESTING

Magnetic

& die

particle, and

Die

penetrant

- Grouting of engine block water jackets

- REMOVAL OF PLUGS FROM BLOCKS, HEADS, CRANKS, TAPPED FOR NPT BUNGS

- ROBII SURFACING MACHINES, BLOCK N HEADS.

- BELOW OPERATIONS FOR THOSE NOT CONFIDENT TO DO THEMSELVES,

- or do not have the Time

- RING

GAPS: CHECKED & SET

- BEARING: CLEARANCES CHECKED AND SET:

- CAM TIMING, PUSH ROD LENGHTS, ROCKER GEOMETRY CHECKING

- TRIAL ASSEMBLING TO CHECK DECK HT. ROD TO BLOCK & CAM & OIL PAN

- CLEARANCES